PR 00310: verschil tussen versies

(Student experiences added) |

(Added pictures) |

||

| Regel 6: | Regel 6: | ||

The influent water used in the research consists of effluent from a local Membrane Bio Reactor (MBR) and effluent from an industrial wastewater treatment plant (Biox). These influents will be tested separately and also as a mixed stream, with and without wetland treatment. | The influent water used in the research consists of effluent from a local Membrane Bio Reactor (MBR) and effluent from an industrial wastewater treatment plant (Biox). These influents will be tested separately and also as a mixed stream, with and without wetland treatment. | ||

[[Bestand:Wetland construction.png|gecentreerd|miniatuur| | [[Bestand:Wetland construction.png|gecentreerd|miniatuur|830x830px|Wetlands North and South under construction]] | ||

[[Bestand:Wetland | [[Bestand:Wetland pilot 2.jpg|miniatuur|833x833px|A green environment on an industrial site]] | ||

== Student Experiences == | == Student Experiences == | ||

Versie van 2 jun 2021 12:24

Dow, Evides and HZ University of Applied Sciences are working on a TKI subsidized project aiming to investigate how a combination of wetlands as pre-treatment and desalination processes can effectively remove micro-pollutants, nutrients and salinity from wastewater treatment plant effluent. The hypothesis is that wastewater treatment plant effluent is one of the most difficult streams to treat for removal of micro-pollutants and nutrients, so if it can be achieved on this stream then it can also be applied to other streams such as (brackish) surface water. It is believed that the micro-pollutants will be adsorbed in the root zone of the wetland vegetation and the nutrients will be taken up by the bacteria living on the roots of the plants, meaning that the remaining impurities such as salts are removed with a combination of ultrafiltration (UF), ion exchange (IX) and reverse osmosis (RO).

Research on the wetlands alone is carried out independently from summer 2019 to summer 2020. Research on the “brackish water line”; namely the treatment train consisting of ultrafiltration, ion exchange and reverse osmosis in sequence, began in January 2020 and will run until summer 2020 when the wetlands will be connected to the brackish water line as a pre-treatment step. A polishing step such as a mixed bed which would be needed to achieve demi water quality is out of the scope.

The influent water used in the research consists of effluent from a local Membrane Bio Reactor (MBR) and effluent from an industrial wastewater treatment plant (Biox). These influents will be tested separately and also as a mixed stream, with and without wetland treatment.

Student Experiences

Lies Hamelink - HZ Water Management

Lies researched ion exchange (IX) technology as a desalination treatment step after the wetlands with the aim to upgrade the water quality to industrial or agricultural standards.

To provide a sustainable source of fresh water for the industry in Zeeuws Vlaanderen the reuse of effluents streams is researched in a Joint Development Project with Evides Industriewater and Dow Terneuzen. Effluent from the wastewater treatment plant of the municipality Terneuzen and industrial effluent from Dow is treated with constructed wetlands followed by a brackish waterline. This brackish waterline exists of ultrafiltration, ion exchange and reverse osmosis, and is researched for its potential to produce demi water.

An ion exchange unit is used to research the removal of specific anions and cations to desalinate the water and to reduce biofouling and scaling on the reverse osmosis membranes. Ion exchange resins, as the name says, exchange ions during the production, until they are exhausted. Then the resins need to be regenerated to make them functional again. Therefore, chemicals are used, mainly HCl, NaOH and NaCl. Several experiments have been performed on lab and pilot scale to find the most efficient regeneration settings for different resins. To reduce the amount of chemical use for the regeneration, a model will be built to predict the needed amount of chemicals.

The model gives the most effective regeneration parameters to reach a certain operating capacity. The parameters considered are concentration of the chemical, flow rate of injecting the chemical and the contact time of the chemical with the resin. The model is based on data from different experiments. First, it will be checked whether data from the same resins on the different scales are comparable and reliable. Then, functions will be made based on the data, which will be used to build the model.

In the end, a model for three different resins is expected which is based on data from both lab and pilot scale and can be applied on full scale. The model gives the regeneration settings with the lowest chemical use to reach a certain operating capacity. With this model, the regeneration can be optimized and the chemical use will be more effective.

Han Cao - HZ Water Management

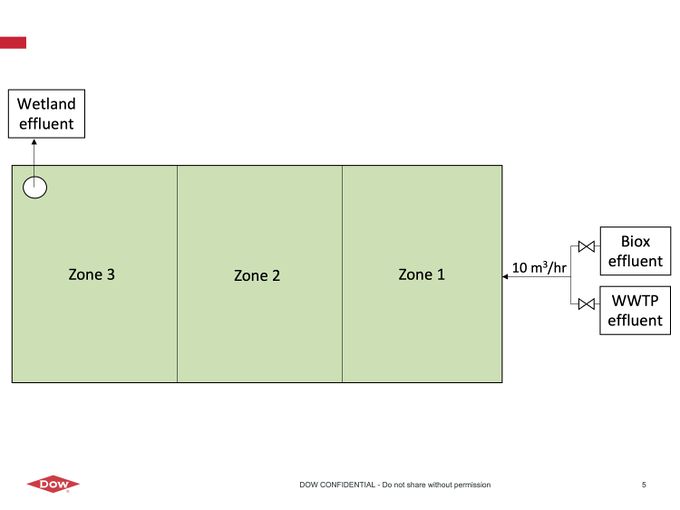

My objective for this research is to find the best operational settings for the denitrification process such as dissolved oxygen (DO) concentration, carbon source concentration, and hydraulic retention time (HRT) in the constructed wetland. The wetland is divide into three zones, and we can control the DO concentration for each zone, currently, we need nitrification first that nitrify ammonium to nitrate, this has to under aerobic condition. Then we have denitrification process, the nitrogen will be removed from the water. So we set the first zone as an aerobic zone, the DO concentration is around 2.5 mg/L. The second zone will be an anaerobic zone for denitrification, there is a carbon dosing system at the beginning of this zone to provide a carbon source for denitrification, by setting different carbon dosing concentration to find the best carbon and nitrogen (C:N) ratio. The last zone will be an aerobic zone again in order to biodegrade the organic carbon. Besides, on the site, I daily check the wetland situation, monitor the influent and effluent parameter. I also take grab samples to double-check with the online sensors.

Wetland configuration:

Wetland construction finished:

Wetland influent system:

Louis Johnston: Aquatic Eco-Technology

As part of my 3rd year studying Aquatic Eco-Technology B.Sc. at the HZ University of Applied Sciences, I was offered an internship at DOW Benelux on a new pilot project looking to reduce the company’s reliance on fresh water taken from the Biesbosch. I applied for the internship because I wanted to gain more of an insight into DOW’s operations as a global company and sustainability activity. Furthermore, I wanted to establish how such a global company acts on its sustainability goals and how easily environmental issues can be made economically viable.

The pilot project at DOW explores the reduction of the company’s reliance on Biesbosch water (currently at 20%) on a pilot scale, with the goal of running a full scale system once optimization of the treatment steps have been fully explored. The company objective is to reuse 100% of used water by 2025, with a constructed wetland as the first pre-treatment step.

My role between September 2019 and January 2020 consisted of optimizing and maintaining the wetland before its connection to further pre-treatment pilots in June 2020. Over 4 months, I encountered troubleshooting difficulties, carried out dissolved oxygen tests, tracer tests, and performed daily grab sampling, comparing the COD and NO3 with the analyser results to test reliability becoming an important task. I also monitored the dissolved oxygen, temperature, pH, flow, and total suspended solids of the wetland, reporting weekly and monthly to the larger team.

Upon comparing myself to when I first started at DOW, I can see that I have gained important professional qualities which will be incredibly useful in the future. Students from UGent and TU Delft, Evides, lecturers from the HZ, and companies in the construction industry were all involved with this project created a very dynamic working environment. I was able to realise the importance of what I was doing and the responsibility that I had, and could then find a way to support the team whilst gaining a great deal myself. I am thankful for the opportunity.